Read Calibration on E92 With Efi Live

In 2014 Gasoline Direct Injection (GDI) V8 power controls striking the scene, and what defoliation there was! Now enter 2019, the concept of GDI has taken on a household name nonetheless many all the same await upon it as a mystery. Follow forth as we endeavor and deflate all the internet buzz and spotlight some of the tools needed today to go it nether command.

You must starting time remember that the internal combustion engine has remained virtually the same since its inception, which is well over 100 years ago, and for this, the basics still utilize today. We all at this betoken should recognize that the engine is an air pump. The downward stroke within the cylinder creates a depression pressure which then draws high-pressure air from the atmosphere. Throwing some fuel into the mix, compressing it and lighting information technology off creates the energy needed to produce power.

By the laws of physics; airflow and torque have a straight correlation. Why is this important? It's considering it's the basis of today'due south torque-based engine management control systems.

Since the beginning of General Motors hard entry into fuel injected engines — let's say in 1997 when the LS motor was released — they have used two distinct methods to measure this airflow into the engine. These would be noted every bit Mass Air Flow (MAF)-based which is direct-measured, and Speed Density-based which is calculated. The logic behind the use of two air models is that the Speed Density fashion is improve for transient changes and the Mass Air method is more authentic during steady land conditions. Transient is when there are quick changes to throttle/load whereas the MAF works very well during linear airflow. Since both of the conditions are continually varying, it'southward crucial that both models agree. The factory has spent endless hours to define these functions which have made today's cars pretty seamless to drive. Still, when y'all decide to modify your engine, all goes haywire!

Mass Air Flow Model

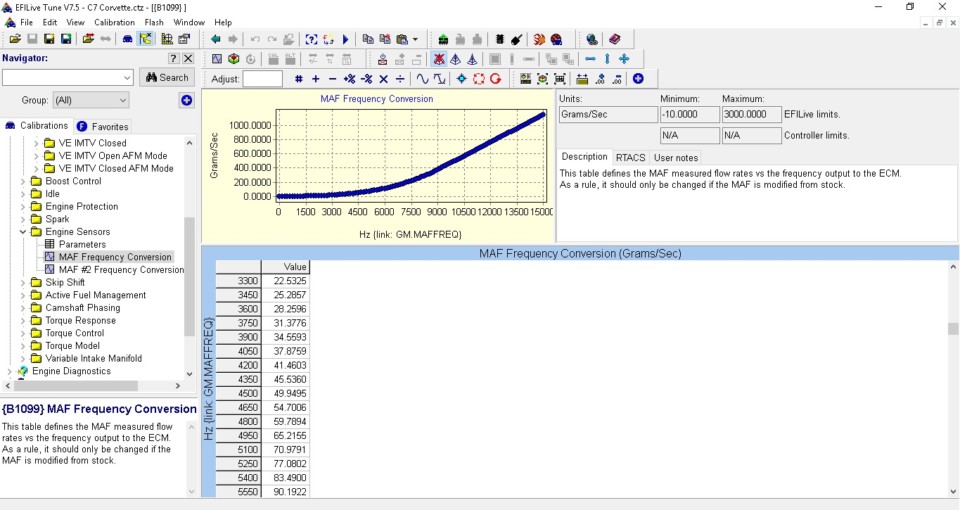

The Mass Air Flow Sensor is the kickoff sensor in the chain of ingesting air. Whatever changes made to the inlet tract from the factory volition crave a correction to the MAF curves in the car's ECU. An first-class instance of this could exist the use of a large 5-inch aftermarket common cold air intake or the four-inch new inlet pipage on your centrifugal supercharger.

As airflow travels past the MAF sensor, it converts a measurement of hertz to grams/second values. The ECU uses these values to summate fueling, as well in grams/seconds, so the right proportion of air and fuel are mixed which is essential for engine operation. In the early years of MAF based systems, this was all the MAF needed to do. Today'south new controllers have this another stride further by using that grams/second value and converting information technology to a torque value in Newton Meters. Concord this thought every bit nosotros will come dorsum to it.

Speed Density Model

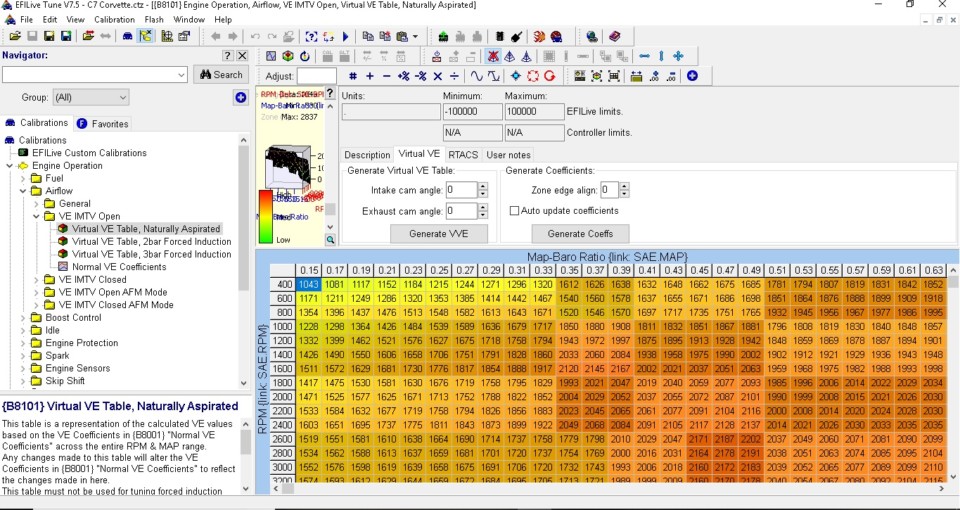

The Speed Density model is a bit more complicated equally fourth dimension has evolved. SD has been around in aftermarket controllers for years and looks at manifold pressure level, engine RPM, and temperature, then references to a "look upward" value. This form of air modeling is much more specific as the values demand to be correct and remain as they are vs. MAF which tin can vary with mass over time. In 2006 GM took this to a whole other level using a complex seven string polynomial calculations to determine this value, aye big words and for a good reason. Today's modern engines are non equally two dimensional anymore equally they once were. With variable valve timing, variable manifold runners, flex fuel and various forms of factory forced consecration; today's engines tin can vary their volumetric efficiency on the fly based on demand. If this were done through a ii-dimensional table, there would need to be thousands of them in a controller that would most likely need to take upwardly the entire torso. This is where the polynomial calculation comes into play. Like any equation, in that location is input information which eventually solves something. In this instance, the calculation looks at RPM, Manifold Absolute Pressure (MAP), temperature, spark, and camshaft degrees.

Unfortunately, the tools needed to extrapolate these values accurately is in a higher place most enthusiasts' pay course. Nonetheless, the aftermarket has created some tools to get us closer to the resolve.

What'southward important is that both models, as dissimilar as they are, must report the same air mass for the system to piece of work correctly. The process to exercise this properly is best left for another writing equally it gets quite involved.

Torque Based Command

Today's controllers (such as the LT1's E92) now use torque as its primary target of control. Over again this is natively expressed in Newton Meters (NM) of torque. Nosotros can take a look at idle every bit a simple case. Anyone who has ever assembled an engine has manually spun the engine over on an engine stand and felt the resistance and elevate of all the moving parts. If you take a torque wrench, yous tin can approximate how much torque is needed to rotate it. For an engine to idle you need to produce more than torque, so the value of resistance or the engine will not idle. Going back to the rule of torque and airflow go manus and hand, as you tin run across nosotros need to move more than air to make added torque to overcome the friction. Not enough air and it won't idle. Too much air and information technology will idle high.

When you lot decide to turn on the Air-conditioning, y'all add more load to the engine and therefore need more torque. Then the ECU commands the electronic throttle torso to fissure the blade and provide this air and make more torque. While this is an example of adding torque, much of the torque based control arrangement is utilized to take torque away.

The manual, traction command, and torque management all office by removing torque.

The transmission determines its shift patterns and characteristics based on torque. This information is transmitted from the engine controller to the transmission controller, which is why the engine scale must be on indicate. You can't put 480 nm of torque through a transmission that is expecting 300 nm. If this is the case, significant wear or damage to the transmission is expected.

Everyone seems to throw the words "torque direction" around as if it's the plague of the car. This is far from the truth. Torque management is exactly every bit it states, a logic to manage the torque. Well, you might say: who cares? The OEM utilizes this strategy so they can keep the vehicle from breaking under adverse conditions and provide a warranty. If the rear axle tin simply handle four,500 nm of beam torque and the engine is now capable of producing 5,000 nm; the controller can request a torque reduction via pulling the throttle and reducing spark timing. This same logic as well applies to the transmission as well as traction command. Yous tin now get-go to see why things are torque based.

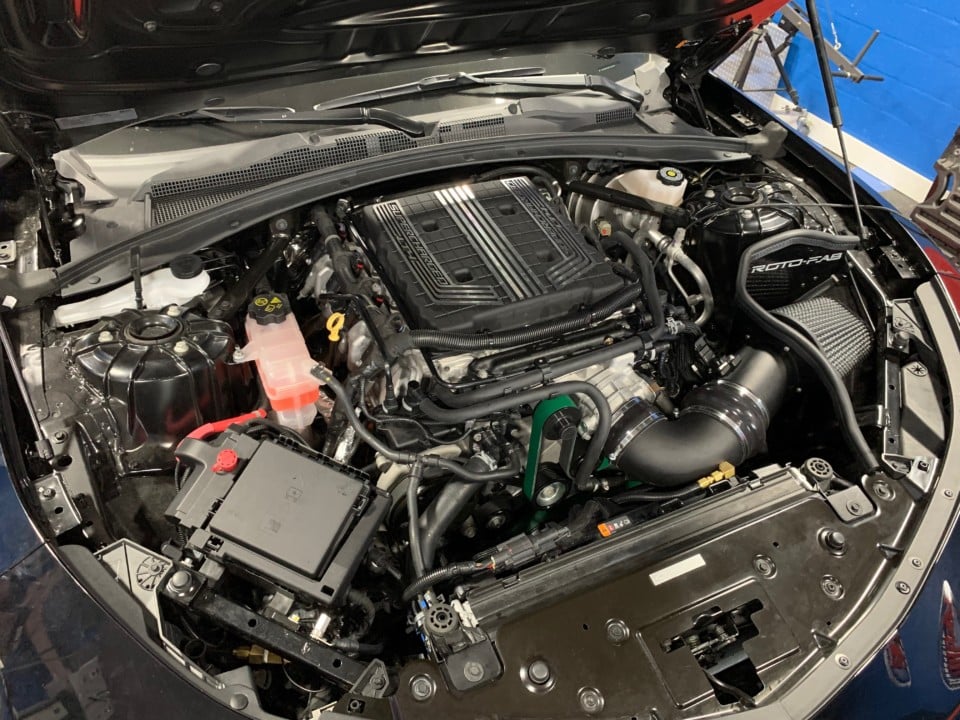

Now let's expect at what happens when we get-go to increase the output of an engine. Permit's say nosotros take a 2018 ZL1 powered with the LT4 supercharged engine and jamb in a bigger camshaft while swapping the stock ane.7-liter supercharger for a Whipple 2.9L, and include all the other trimmings, before strapping it onto the rollers. At this bespeak, it'south condom to say that all these changes were not what the original calibrator had in mind. That mammoth five-inch cold air intake is sure to skew the stock MAF transfer role, and in that location is no doubt the larger camshaft has moved the engines volumetric efficiency to the n of its stock location. For the engine to perform correctly, these volition have to exist stock-still to ensure fueling is correct and subsequently the final torque values that are derived from the airflow.

Focusing on the MAF transfer function, start nosotros need to reestablish a new curve that provides the controller the correct airflow to Hertz. Here is the table for the MAF that needs to exist addressed.

To solve this problem, we would demand to force the controller into open loop every bit we practise not want whatsoever contribution for correction to come from the oxygen sensors. It's also essential to ensure nosotros are commanding a lambda of 1, for this example that volition equate to fourteen.2:1 air-fuel ratio, which is stoich for today's pump gas with up to 10% ethanol. Using a load control chassis dyno, we can so hold the vehicle at the load breakpoints every bit divers in the MAF bend. If you note that you commanded lambda and lambda is off, you need to correct the error at that specific hertz pause point. Once this has been performed for all cells, the new curves values will represent the bodily airflow.

Now we demand to address Speed Density, which is a bit more tedious. Still, thanks to some great tools within the EFI Alive software this process has go much easier. Since the old style 2-dimensional volumetric efficiency surface table no longer exists, EFI Alive has congenital a tool that allows the user to work off a "virtual" table that is represented similar a 2d table just calculates the engineering coefficients that the modern controller uses for its fuel calculations. The following shows this table.

Once more using a load controlled dyno, yous can sweep through the different cells until as many are filled with the correct values. Once they are right, the speed density model will represent the correct airflow at those loads in which these values can be converted to torque.

One of the first tables in the chain of torque controlled system is the Driver Need table. This tabular array represents driver input, via the accelerator pedal, which is then converted to a torque request. Depending on whether the vehicle is a transmission or automatic transmission, the values in this table will either exist kilowatts or axle torque respectfully. The torque asking is then sent to the role of the controller that handles the electronic throttle command. This asking is made through a adding called the compressible gas formula. In layman's terms, information technology determines a target manifold pressure which is determined by the throttle blade opening. Loftier-pressure air enters the manifold changing this pressure, which is how about drive-by-wire cars connect the pedal to the blade.

At present the fun begins!

Before the blade tin open to its terminal angle, more decisions must exist made inside the controller'due south logic. Throughout the controller are numerous tables that are limited to how much power can exist made. From the factory, these tables are typically just higher up the engine's max power output and don't typically hold back a lot in max power. However, the installation of high-performance parts will virtually likely move power into these limits. For this, the tables demand to exist modified. Beneath are a few tables that tin can limit you reaching your goals.

Now that we hopefully have moved these limiters out of the way, we need to contend with other controllers that are waiting to see what the new torque output of the engine is. These being controllers like traction control, transmissions, and drivetrain role protection.

Traction Control Intervention

So you pull out on the avenue after all your upgrades and stab the pedal to the flooring. The nuance lights upwards like a Christmas tree, and the car feels very underwhelming. The traction control organisation is in the chain that connects your big right foot to the throttle blade. With numerous sensors ratting you out that the rear wheels are spinning 200-percent more than the front, the throttle is at 90-per centum, and the brake organisation reports force per unit area on the pedal. The engine controller removes torque which is done through both throttle closures and spark retard as both of these take power away.

Transmission Control

Today'southward transmission is quite a marvel of engineering. Then much is going on inside the transmission that for information technology to work correctly, specific strategies have been employed to control all of this. I accept often used the example of a relay race every bit a way to explain how an automated transmission makes a shift. Moving-picture show the first guy starting down the track holding the baton. We will telephone call him First gear. He leaves from a dead terminate and accelerates as hard as he can towards the side by side guy whom nosotros volition call Second gear. As the kickoff guy starts budgeted the 2nd guy, the second guy needs to outset preparing for the handoff. If he stands there almost likely the kickoff guy will pummel him over and drop the baton. So for this transaction to get seamlessly, we need to start creating an environment where they can brand the handoff. Typically what happens is the second guy starts building some speed with the hopes that by the fourth dimension the first guy is in handoff range, they are at a like speed to be able to make the handoff. In essence, time slows downwardly, and a smooth transfer happens.

At present getting off the running track, we need to sympathise that the manual also needs to take a moment where the gear handoff can be made. Often what you will find is the transmission asks the engine to slow downwardly the inertia and ability at that moment and then the parts internally tin can make the shift. In one case the shift is made it puts the engine dorsum into full ability. This is the basis of the words "Torque Management," which in this case is not a bad thing. From an OEM standpoint, it's what provides the ability to continue a solid warranty, and from a operation aspect, it keeps parts alive under higher loads. It can exist a subjective range of how much, so tread lightly.

In closing, it's safe to say the theory backside torque based controls is elementary. However, the logic behind it tin exist much more avant-garde and will continue to evolve fifty-fifty farther.

Source: https://www.lsxmag.com/tech-stories/an-inside-look-at-torque-based-tuning-with-efi-live/

0 Response to "Read Calibration on E92 With Efi Live"

Enregistrer un commentaire